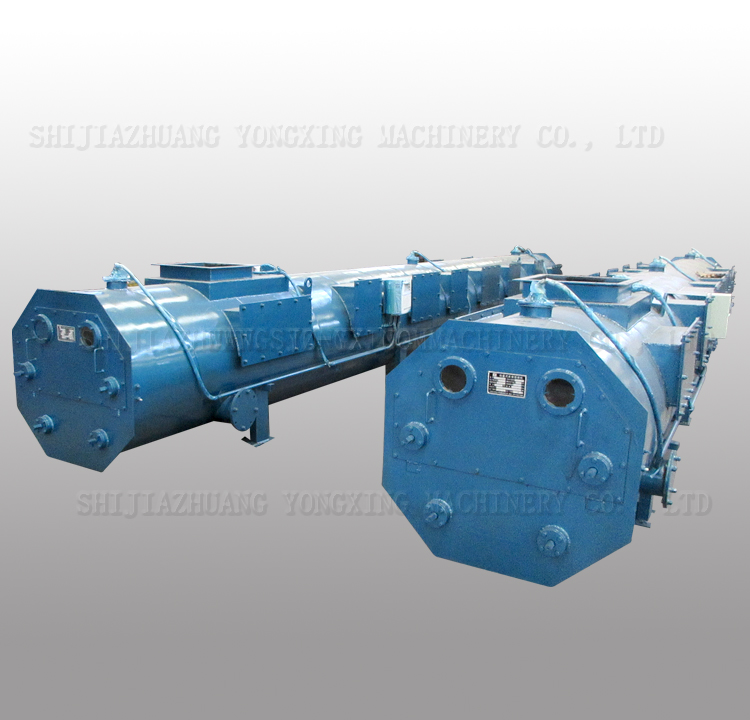

Weighing coal feeder

The weighing coal feeder receives the coal from the upper bin through the import chute, and transports it to the next level equipment through the belt conveyor. The weighing bridge installed under the conveying belt transmits the weight of the coal to the weighing sensor in real time. The weighing sensor measures the unit weight of the coal on the belt and feeds it into the instrument. The speed sensor installed on the tail drum measures the belt speed in real time. The speed pulse output is proportional to the belt speed and also feeds it into the instrument. The speed signal and weight signal are sent to the instrument controlled by the microcomputer for accumulation processing to generate and display the actual flow and the accumulated weight of coal. The instrument also compares the instantaneous flow of coal on the weighing roller with the set flow of coal feeding, generates the control output signal to the frequency converter to change the driving speed of the coal feeder, so that the coal flow on the coal feeder changes, approaches and maintains the set flow of coal feeding, so as to achieve the purpose of quantitative coal feeding.

The weighing coal feeder receives the coal from the upper bin through the import chute, and transports it to the next level equipment through the belt conveyor. The weighing bridge installed under the conveying belt transmits the weight of the coal to the weighing sensor in real time. The weighing sensor measures the unit weight of the coal on the belt and feeds it into the instrument. The speed sensor installed on the tail drum measures the belt speed in real time. The speed pulse output is proportional to the belt speed and also feeds it into the instrument. The speed signal and weight signal are sent to the instrument controlled by the microcomputer for accumulation processing to generate and display the actual flow and the accumulated weight of coal. The instrument also compares the instantaneous flow of coal on the weighing roller with the set flow of coal feeding, generates the control output signal to the frequency converter to change the driving speed of the coal feeder, so that the coal flow on the coal feeder changes, approaches and maintains the set flow of coal feeding, so as to achieve the purpose of quantitative coal feeding.

The belt type weighing coal feeder is developed by absorbing the advanced technology and experience at home and abroad, and has unique anti deviation measures

● adopt flame-retardant tape around skirt to effectively prevent materials from falling.

● the support adopts section steel structure, with high overall rigidity and good stability.

● the coal feeder adopts motor frequency control, which is easy to control.

● there are two types of feed gate, manual and electric, which are configured as required.

● the discharge gate is an electric gate driven by an electric actuator, which is easy to install and adjust. In case of over temperature, the gate will be closed automatically to protect the safety of the whole set of equipment.

● the feed port is equipped with a shaping gate to adjust the thickness of the coal seam of the belt and improve the accuracy of PID regulation.

● it has the functions of coal blocking, coal breaking, chain breaking, ultra temperature belt deviation alarm.

● the head is equipped with an anti deviation switch, and the lower part is equipped with an automatic deviation rectifying device to effectively control the belt deviation.

● coal blocking switch is installed at the outlet to monitor coal blocking.

● the bottom of coal feeder is equipped with fly ash cleaning device, which can complete the function of fly ash cleaning.

The fully enclosed shell adopts the upper and lower separation structure, with good sealing effect and convenient disassembly, especially for belt replacement.

● there are multiple observation windows on the shell, and the interior is equipped with lighting indicator light, so as to observe the operation condition of the equipment.

● all lubrication points are on the outside of the housing.

● the electrical control box can be installed in the coal feeder body or in the electrical control room.

● easy on-site wiring and maintenance.

Company:Shijiazhuang Yongxing Machinery Co., Ltd

Contact:Mr.wen

Tel:86-311-88219661

Mobile:86-18931860549

E-mail:sjzyxjx@163.com

Address:97 kilometers of HENGJING Road, Luancheng District, Shijiazhuang City, Hebei Province, China